The component libraries in Altium Designer are integrated into the schematic editor, so selecting and placing components are easy tasks. With a set of schematic design and organization tools, you can quickly create circuit designs and select components for your new system. Your schematic editor is where yous start your new circuit board design. What should you be looking for when you motility from a free software platform to a fully functional computer-aided PCB blueprint system? Become Started with the Best Schematic Editor This often includes rigid-flex materials, ability distribution for small, high-power boards, and all this while ensuring your design keeps manufacturing in heed. The level of technology that Circuit Board designers are required to use in their circuit board designs, oftentimes demands more functionality beyond what a complimentary software version is able to handle. They were able to get their designs done and hands motility on to the next project.

Apply Altium Designer if yous need the all-time PCB design & layout software.įor years PCB designers accept been content to piece of work with free PCB design tools.

#Fab cad software free download professional

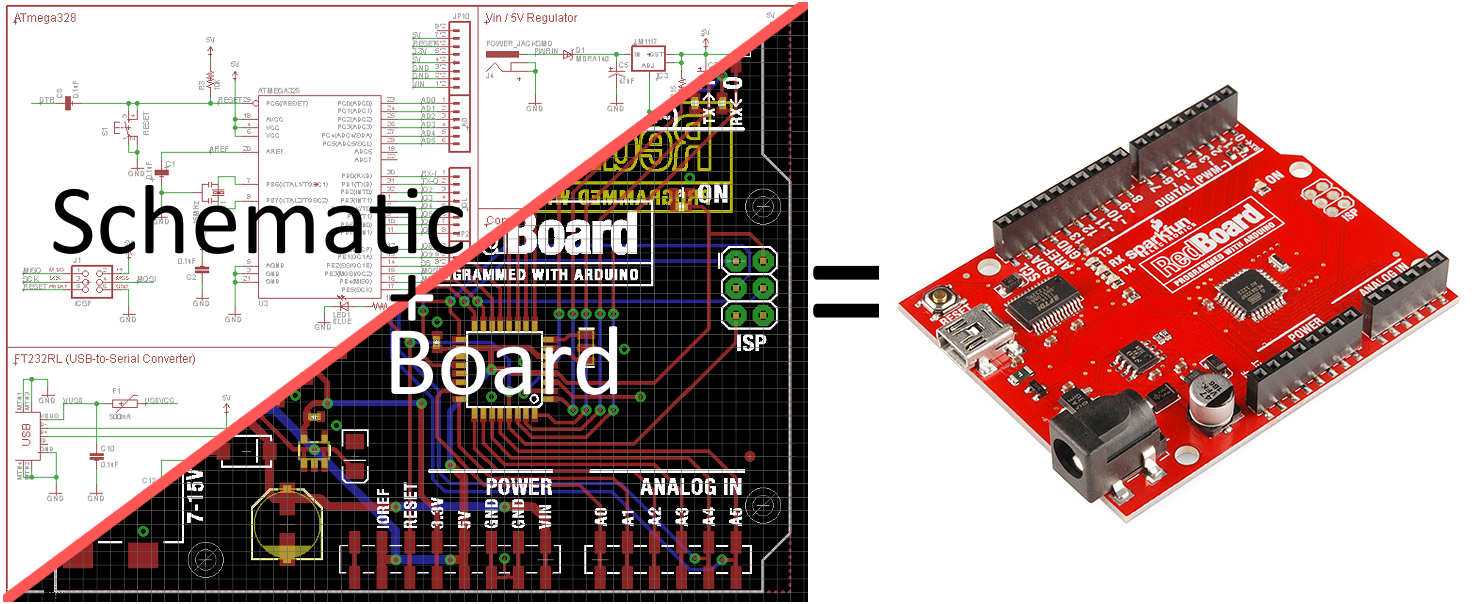

The well-nigh powerful, modern, and easy-to-use printed circuit lath pattern programme for professional use. Try Altium Designer for your next excursion board design. Instead of stringing together multiple programs, use the only PCB design platform with everything you demand for circuit blueprint, layout, and manufacturing. When you lot have a set of design tools to create a circuit board and prepare it for manufacturing, you need a consummate set of tools that aren't found in a free PCB pattern software download. These include bill of materials compilation, generation of Gerbers and other deliverables, and data management functions. There are other of import functions yous won't find in free PCB design software. These include the basic functions of schematic design, schematic capture, placing parts, and routing traces. Overall, precast processes differ so significantly from conventional construction projects that special software is required for prefabrication.When designing circuit boards, there are some functions that your PCB (printed circuit board) design tools must excel at without exception.

The production conditions also play a decisive role – factories can ensure high quality precast concrete elements consistently, regardless of the weather. A key advantage is also the extraordinarily precise cost and schedule predictions that result from meticulous production planning. Through digitalization and automated processes, industrialized construction enables greater efficiency, shorter lead times, and higher precision. There, a crane takes over assembly and lifts the precast parts into place. When prefabricated parts are used, building components are prefabricated to the millimeter in production halls and then transported to the construction site as they’re needed. The industrial prefabrication of building components is the key to increasing productivity in the construction industry. Solution approach Increased efficiency through prefabricated construction

0 kommentar(er)

0 kommentar(er)